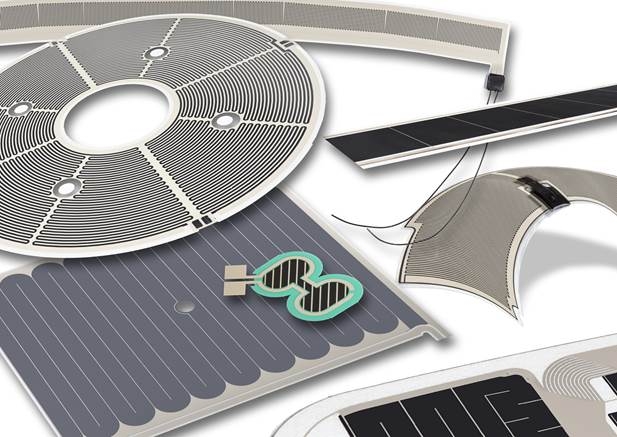

Heating Foil Assembly

Together with our partner, flextem GmbH, we develop and assemble customized solutions for a wide range of applications in the battery industry, automotive and medical technology, white goods, and industrial electronics sectors.

The assembled foils are available in constant resistance or PTC variants. The latter require no additional control or monitoring due to their self-regulating properties.

For assembly, we use existing contact systems from TE Connectivity but also employ specially developed contacts that can handle currents of up to 13 A, making them ideal for high jump-start currents in battery heaters.

The foils are encapsulated using the low-pressure molding process to protect the sensitive connection areas. This process provides excellent mechanical stabilization, protection against environmental influences, and electrical insulation. The encapsulations can be customized in various shapes (e.g., snap hooks, mounting holes, etc.).

By using special, low-viscosity hot melt adhesives, we ensure optimal adhesion and durability of the encapsulated components. Our process enables high reproducibility, short cycle times, and cost-effective production – from encapsulating prototypes, small and medium series with a hand gun, to large-scale production using fully automated systems with cooled tools.

Each heating foil undergoes 100% testing, optionally documented, and marked for batch traceability.